Dan (Littco) rebuilt the turbo for me yes mate, although it's originally built by CR turbos

It's a ko4 frame, with a RS6 turbine wheel with 7 degree clip, and a 2283 billet compressor wheel. B5/Littco ported hotside, and a 1 bar actuator. Price wise I couldn't say, as Dan just rebuild this one. The original unit from CR was around £950, but I believe Dan can do them for much less.

I havn't got my own build thread, so I'll add todays excitment in here instead:

I bought a VW Motorsport Billet alloy shifter

It won't make the car any faster, or lighter, but it will make me smile every single time I use it, because it's just so damn cool. It's something I have wanted for YEARS since I first saw one on a race car many years ago.

The unit seems really nicely made, both the pivots are on bearings, and it has an awesome little lift collar to engage reverse.

The only complaint I could find about these, was the lack of self centring on the lever from left to right, so I decided to try and come up with a solution.

That's where a tractor brake pedal return spring comes in.

it'll be fitted over the main shaft like this:

But in between the unit body, and the main left-right pivot body, with 2 small dowel holes drilled for the tangs:

With careful placement, that should see the lever springing back to centre nicely.

The reverse lock out is also really cool. In normal operation, you push left for first, the these adjustable stops hit this pin like so:

Then you pull this little lift collar:

Which pulls this bike gear cable:

And the pin slides back, allowing you to move further left for reverse!

The welding on the alloy tower supplied seems strong enough, but it's not very pretty, so I'm going to attack it with a flap disc and some wet n dry, and paint the tower Porsche 8C6 orange to match the cage and things.

Cable wise, I've got a set of shift cables from a volvo S40 which are longer to allow me to position the lever where I want it, and I'll be making up custom cable stays from 3mm plate, and of course, painting them orange too.

The ball joints I showed earlier, will go on each end of the new cables, so it'll be solidly mounted at each end of the cables for a really tight shift without any rubber in there.

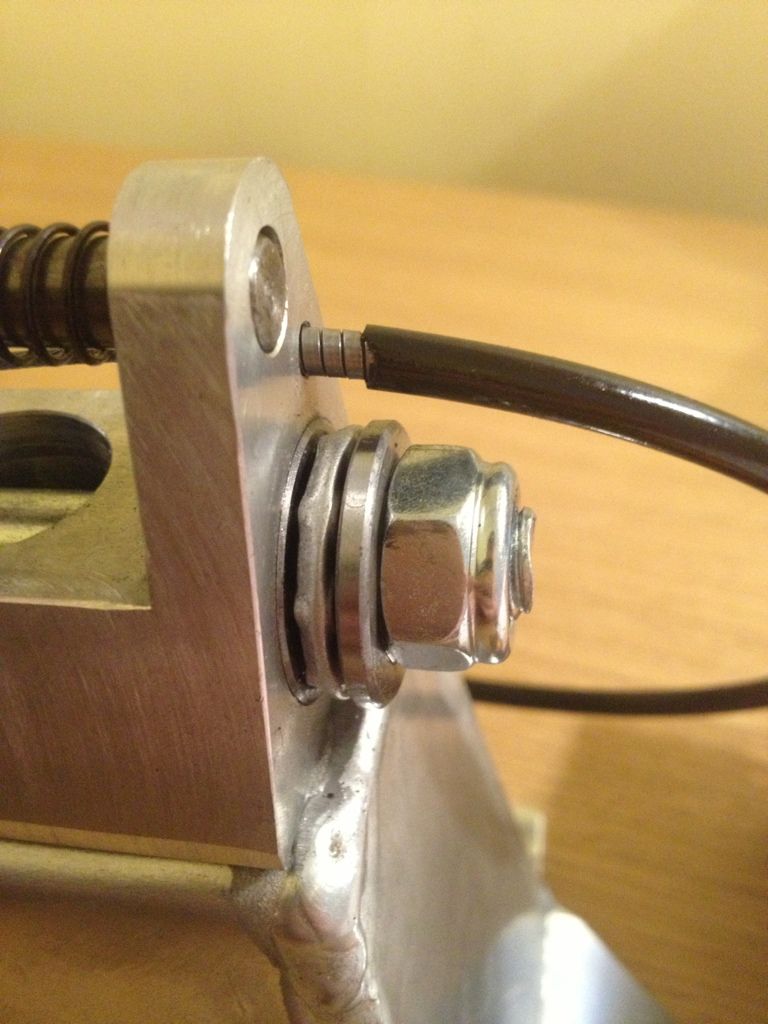

Taking the volvo cables, and cutting the ends off, you can run an M6 die down the rod end and cut on an M6 thread like so:

Then with the aid of an M6-M8 adapter, I can convert the cable ends to an M8 thread:

Then screw on my ball joints:

Sorted! If I need to extend the cables ends at all due to stay placement or anything like that, I also have some M8 threaded sleeves, so I can fit a sleeve to the M8 male end on the cable end, then use some M8 stainless thread bar to get the ball joint exactly where I want it and lock it out with lock nuts.

It's a complete experiment, and I'm sure it'll feel rubbish at first, and take considerable setting up to get it right, but I just love these shifters so much, so here goes!