What about wiring in an N75 switch?

I had exactly the same thoughts as you when I did my build, and I spent £200 on a gizzmo MS-IBC and wired that in.

I gave Niki the option of using that or the N75, and he tried the boost controller, but said that on the road it just didn't feel right on part throttle, strangely also, even when set to 0 duty cycle, the boost level still remained slightly above actuator pressure so you couldn't get power as low as you wanted.

On something like a td05 I'd guess you've got a fairly strong actuator, you may find that actuator pressure still makes pretty impressive figures and is nice and tame to drive for more normal use.

I wired a switch into my N75 and installed it on the dash here:

With the circuit broken the N75 valve remains open and the car runs on actuator pressure, which in my case is 15psi. With the switch on the N75 controls boost as normal and the car runs 21psi

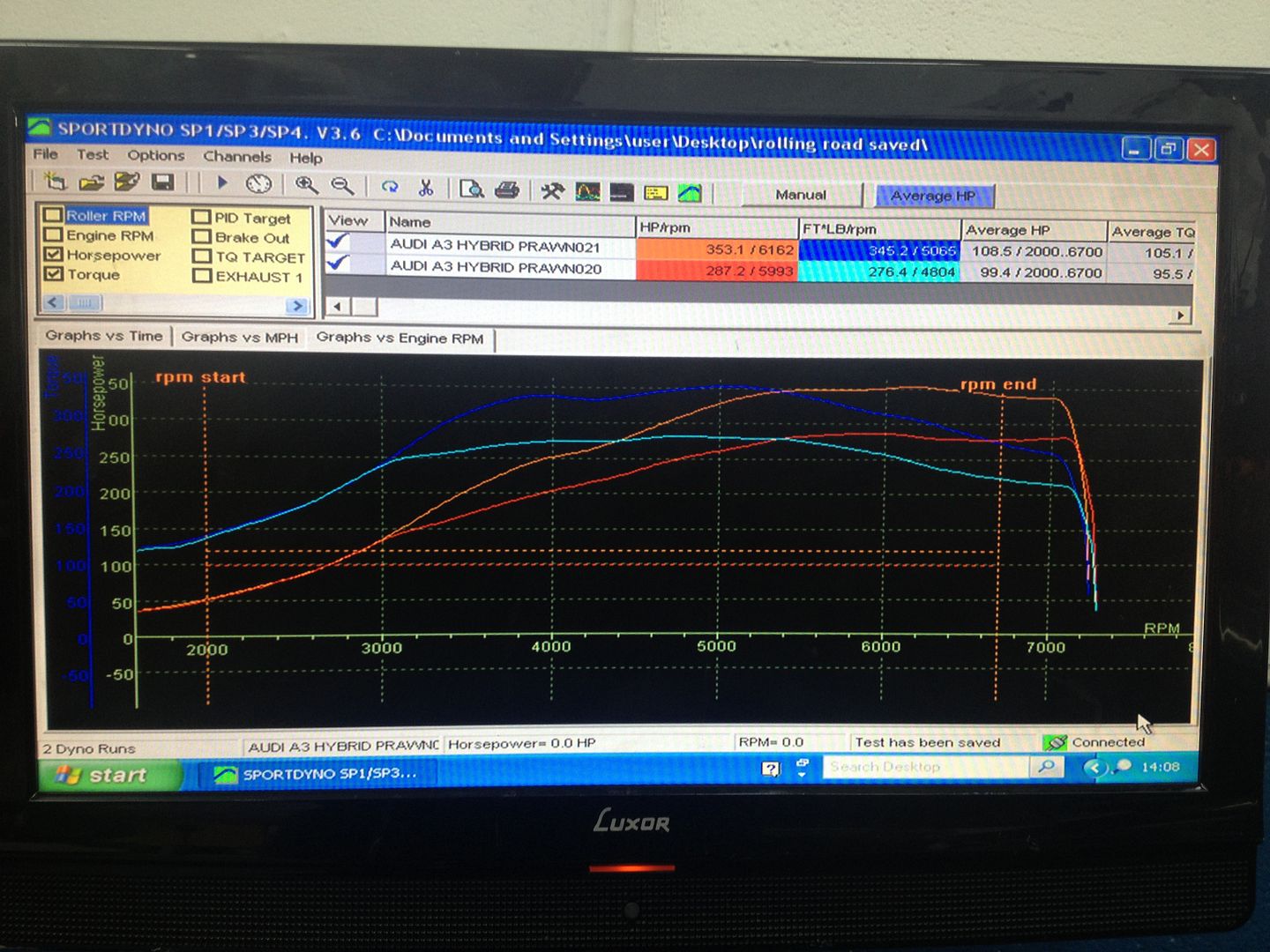

Difference in power curves can be seen here:

It's insanely smooth on actuator pressure, yet still really quick.