So as promised I took some photos to show what I have done / am attempting to do. All work was done with a Dremel Pro and a variety of bits I already had.

First a look at the head before work commenced:

In this first shot you can see the overall condition of the head. I have specifically checked, visually, for any cracks between the valve seats and generally for any evidence of cracking elsewhere.

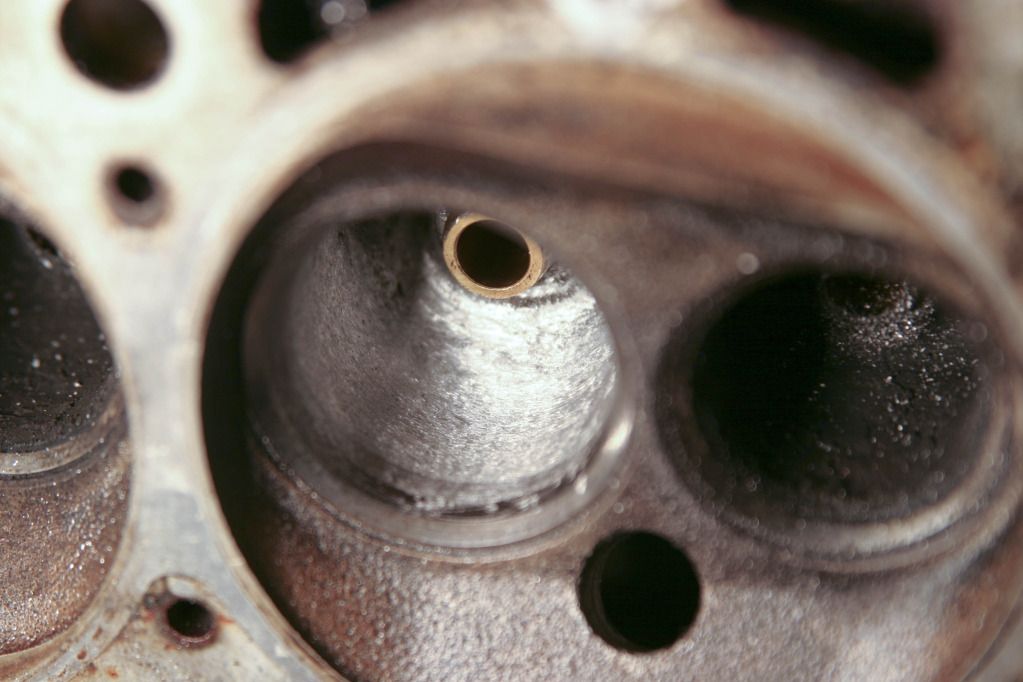

This is a closer look at the valve seat and you can see that there is a ridge between the base of the seat and the throat.

Here I have tried to show that there is a prominent ridge on the wall of the bowl behind the valve guide boss. There are also casting marks / burrs across the port that can be felt with my finger.

For my first attempt all I have tried to do is smooth out the obvious casting marks and blend the ridge into the wall of the port. I used some small carbide tips i had and a speed of 22000 rpm. This seemed fine with gentle pressure and a bit of patience.

The initial results are as follows:

I first tried to blend the valve seat into the throat to get a continuous surface. This was achieved by gently grinding the join until there was a continuous colour change across the whole of the area. When I started there was an obvious line where the two surfaces did not match and I slowly worked until it felt smooth and looked continuous.

Next I delved deeper into the bowl and smoothed out the prominent ridge at the back of the valve guide boss. This took a bit of time, cutting then feeling then cutting then feeling etc, but eventually i got a result that i am happy with. It is not perfectly smooth and the ridge can still, just, be felt but it is much smoother than it was.

I then turned my attention to the inlet. Here there was a very prominent casting burr running down each side into the port. I smoothed these out on both sides.

I then slowed down the speed and fitted a stone to try and further smooth out the walls of the port. The results are as follows:

I am sure that there is much more that could be achieved, i am just trying to go slowly and learn as I go.

Over to you all for comment / critique!

Jon