tappets part deuxso, after rebuilding my tappets (as above), i also managed to kill them by using a magnetic parts tray. so i ordered up some new ones off the bay. i figured if i was dismantling the head again, i may aswell do the stem seals whilst im at it. heres a

pretty handy guide on replacing the seals. start by removing the cam and tappets from the guide above.

Tools Required: valve stem seal pliers, valve spring compressor

Tools Required: valve stem seal pliers, valve spring compressorget all your parts lined up first,

then line up your tools,

its actually very straightforward to do. start by removing the spark plugs in all 4 cylinders. now there is two ways of going about this, pressurise the cylinder with an air hose adaptor or fill the cylinder with about 2ft of rope and turn the crank until its at/near top dead centre. i went with the latter and shoved an old bunjee cord in the cylinder

as i wasn't removing the cylinder head, i had a special compressor which mounts overhead.

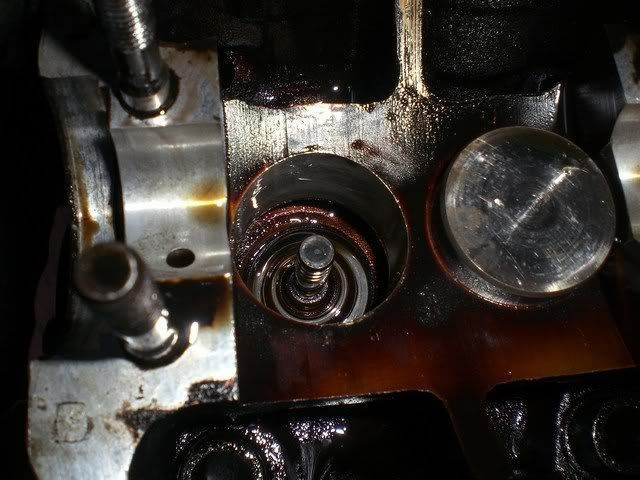

after compressing the spring, get a watchmakers screwdriver and gently push the locking collects out of position. then use a magnetic tool to grab and remove them. with the collets out, when you release the spring compressor the springs will be easy to get to. there is two springs, an inner and outer with a cap on the top and bottom. the bottom cap is under the valve seal and doesn't need to come off.

get your pliers and grab the stem seal, give it a gentle twist and pull it up, make sure you dont grab the spring seat though.

get your new stem seal and give it a coat of oil so it slides down the stem seal without bother. push it down the stem seal until its in place. refit the springs the right way up, put the spring cap on, fit the spring compressor and then reposition the collets. i used a pair of needle nosed pliers to get it roughly in place, then kept poking it with the watchmakers screwdriver until it was in place. when they were sat right, release the spring compressor and go onto the next one.

as 1 and 4 are linked, and 2 and 3 - you can do 4 seals at a time, as long as you stuff both clyinders.

then you can view all the old seals and bin them. remember when refitting the tappets that you need the oil to prime the head. put the cam, rocker cover and timing belt back on, unplug the fuel pump relay and crank the engine. it won't fire and it will turn relatively easily, this should spin some oil around the block and head so its ready to go. refit the aux belt, pas belt put the wheel back on, then start her up and enjoy the lack of oil burning and new tappetly quietness.

its a real quick and easy job, i managed to do mine from start to finish in about 4 hours - and i was working slowly too, it was -4 degrees outside!

to recapshadyP asked me recently how to go about this, so i thought i'd update my post with what i said to him.

I got my tools from

http://www.pvrdirect.co.uk/ - it was a spot cheaper than eBay. Its a really straightforward job. Mark up your crank, aux and cam shaft thoroughly as you're going to need to rotate the cam to do the job. Its easy to put the cam back on 180 degrees out.

Remove the rocker, cam and spark plugs. I used rope to stuff inside the cylinder to stop the valve falling down (otherwise its a head off job). By moving the crank to just before TDC, stuff about 2 feet of (non-fraying) rope into the spark hole, then turn the crank until it hits TDC and you meet a fair amount of resistance.

Remove the tappets, use a cloth and some wide grip pliers to get them out. They're only held in by gravity but they're seriously hard to grip with your fingers.

Fit the overhead valve spring remover and put pressure down on it, if the valve starts to go down with the spring - then you need to just re-position the rope a bit. If you've got an air compressor you can get an adaptor to fit in the spark threads to pressurise the cylinder.

Once you've got the pressure on the spring, there is two metal collets that bite onto either side of the top of the valve stem. I used a telescopic magnet to grab the collets, but BPB disagrees with this method - DannyP says to use a cable tie with a blob of grease on the end. Either way, collets come out, then release tension on the spring compressor.

You'll have 3 bits, the outer spring, inner spring and spring cap - try and remember which way round these went in! Then you need to remove the stem seal, its at the bottom of the valve stem usually obscured by oil. Using stem seal pliers grab the seal and pull it upwards. It doesn't take a massive amount of force, be careful what you grab as its easy to pull the spring seat up too.

Replacing the seal is easy as coating it in oil, coat the valve stem in oil, then slide it down, using the pliers push it into the valve spring seat. Put the outer, inner and spring cap back on, refit the spring compressor and put the collets back in place - I found using long nose needle pliers to position them and a small watchmakers screwdriver to poke it into the exact position works well. Release tension on the tool and thats it.

Because of the firing order, 1+4 then 2+3, you can do Cyl 1 and 4 at the same time and 2 + 3 at the same time (as long as you do the rope trick / pressurise simultaneously).

Refit the tappets, cam, give it all a splash of oil, rocker cover on, timing belt on and away you go!

it snowed